Report:- Carnaud Metal Box Engineering visit….

In November 2025 we were invited to visit Carnaud Metal Box Engineering in Wortley, Leeds and our host was John Crabtree, Mechanical Engineering Manager. LAE Member Neil Cobbold kindly offered a report on the visit as follows:-

“We all arrived at the Wortley site in good time. Howard reversed parked like a professional !

John Crabtree greeted us and we walked around to the boardroom, which was like all of the site, very impressive, but we all quietened down when asked if we had read the induction bumf, to be given a exam on it, thanks CMB, we did one so we didn’t have to get them marked, as we may not all get 100% !

Here is a link to the company’s preview of the site, to give members a glimpse of the size of the operation, quality of the craftsmanship, technology and manufacturing capabilities. https://vimeo.com/949456881?fl=pl&fe=cm

We then moved on to the shop floor, walking across the yard to get there, what an impressive shed, very clean, well lit. Unfortunately the health and safety rules meant we had to wear ear protection (but it was quiet and unfortunately ear plugs weren’t necessary as the levels were well below 85 DB.)

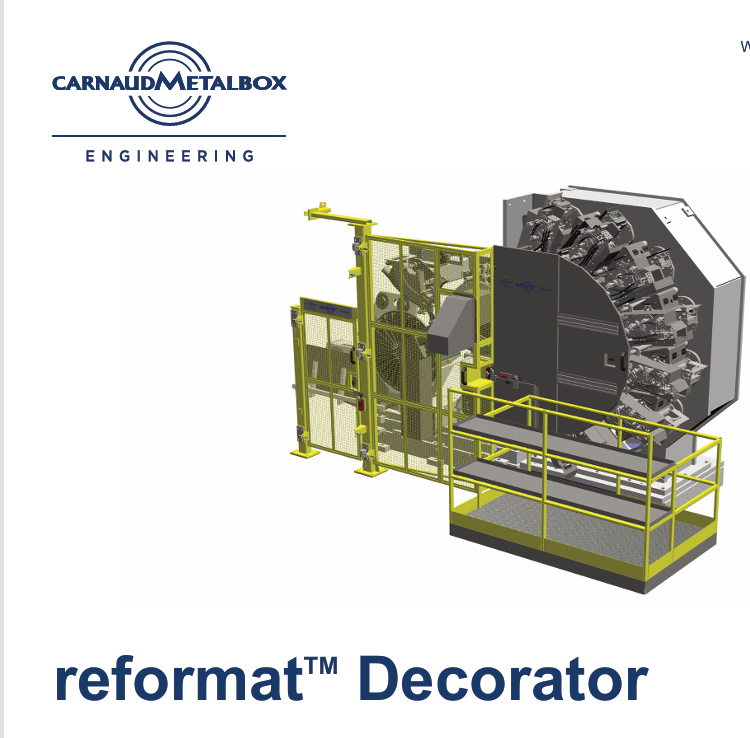

We couldn’t take photos for good reason, so there are a few photos from the company’s website below. The quality of workmanship was evident to all. I appreciated the machining of the parts, the size of some of the line was fantastic.

The press was on site and it was a very big piece of kit, with dies also on show, true quality machining.

The press was on site and it was a very big piece of kit, with dies also on show, true quality machining.

And there were several stations with sundry parts, pipe fittings, fasteners, in quantities… an impressive sight.

The cleanliness was something to be seen.

The machine that puts the print on the can was yet another very interesting piece of equipment, we had seen the video at the presentation and there was a machine on the shop floor with hundreds of cans having been tested to meet customers’ requirements.

John also talked about the company that they had purchased that supply the conveyor system for a better word.

John also talked about the company that they had purchased that supply the conveyor system for a better word.

Then there was a lacquer machine and if you would like to view the machine in operation please click onto the link. https://vimeo.com/956377559?fl=pl&fe=cm

We were all very impressed with what we saw, supplied tea and biscuits and a free pen.

We thanked John and his two colleagues for giving up their own time to show us around. I can (no pun intended !) only imagine machines cycling at 300 cans per minute, the videos had to be slowed down to see it working, amazing.

We may be able to get access to the Shipley plant at Dock Field, where I am sure those interested in machining will be suitably impressed.”

Neil Cobbold – LAE member

.